EcoConcrete - The search for and study of a viable alternative to highly energy-intensive and carbon-positive Portland cement

Abstract:

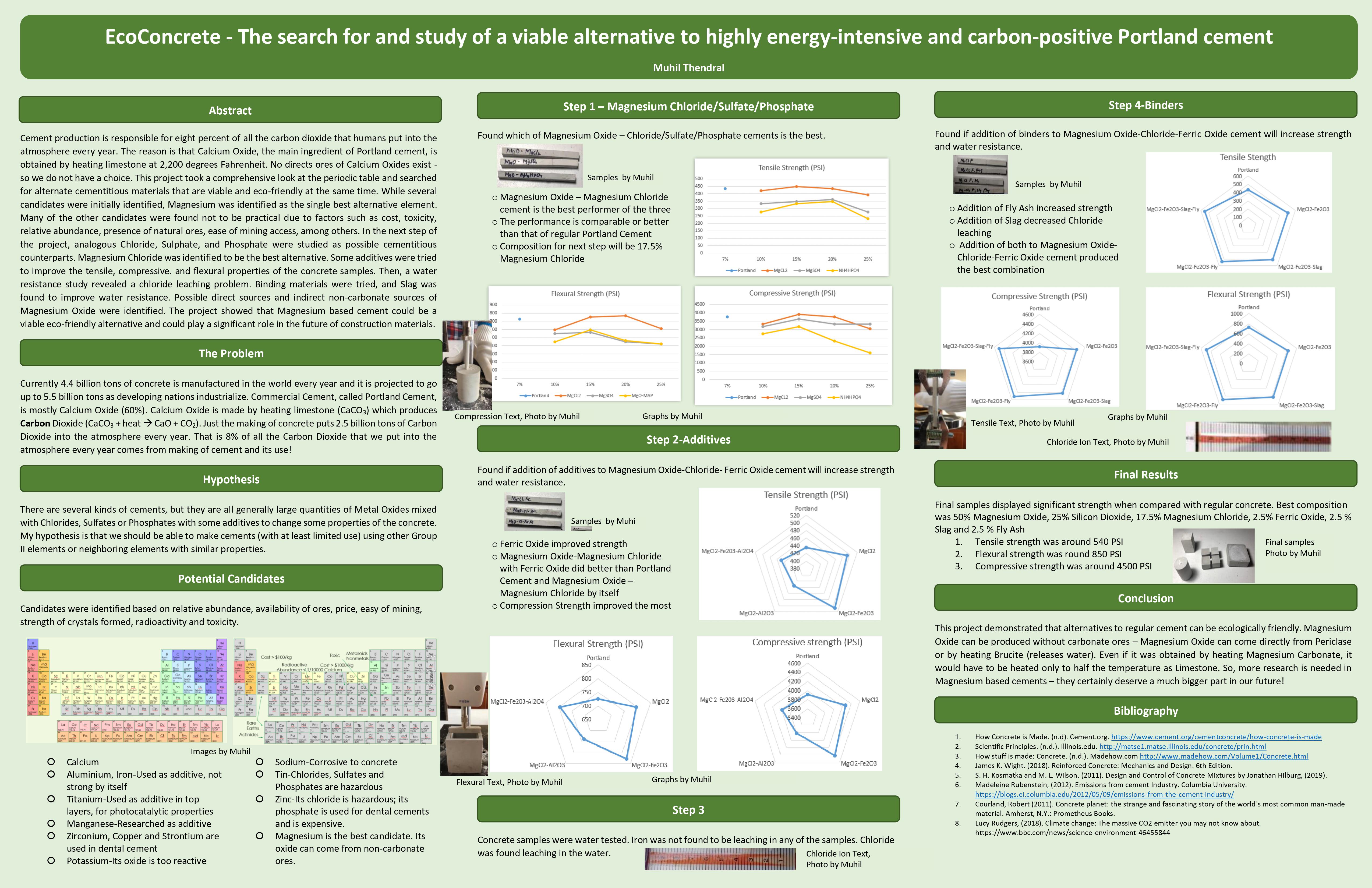

Cement production is responsible for eight percent of all the carbon dioxide that humans put into the atmosphere every year. The reason is that Calcium Oxide, the main ingredient of Portland cement, is obtained by heating limestone at 2,200 degrees Fahrenheit. No directs ores of Calcium Oxides exist and do not have a choice. This project took a comprehensive look at the periodic table and searched for alternate cementitious materials that are viable and eco-friendly at the same time. While several candidates were initially identified, Magnesium was identified as the single best alternative element. Many of the other candidates were found not to be practical due to factors such as cost, toxicity, relative abundance, presence of natural ores, ease of mining access, among others. In the next step of the project, analogous Chloride, Sulphate, and Phosphate were studied as possible cementitious counterparts. Magnesium Chloride was identified to be the best alternative. Some additives were tried to improve the tensile, compressive. and flexural properties of the concrete samples. Then, a water resistance study revealed a chloride leaching problem. Binding materials were tried, and Slag was found to improve water resistance. Possible direct sources and indirect non-carbonate sources of Magnesium Oxide were identified. The project showed that Magnesium based cement could be a viable eco-friendly alternative and could play a significant role in the future of construction materials.2-minute Video Overview: https://youtu.be/6m-HEdyJKBM

Bibliography/Citations:

Bibliography

- How Concrete is Made. (n.d). Cement.org. https://www.cement.org/cement-concrete/how-concrete-is-made

- Scientific Principles. (n.d.). Illinois.edu. http://matse1.matse.illinois.edu/concrete/prin.html

- How stuff is made: Concrete. (n.d.). Madehow.com http://www.madehow.com/Volume-1/Concrete.html

- James K. Wight. (2018). Reinforced Concrete: Mechanics and Design. 6th Edition.

- S. H. Kosmatka and M. L. Wilson. (2011). Design and Control of Concrete Mixtures by

- Jonathan Hilburg, (2019). Concrete production produces eight percent of the world's carbon dioxide emissions. Archer Paper. https://www.archpaper.com/2019/01/concrete-production-eight-percent-co2-emissions/#:~:text=Currently%2C%20the%20world%20produces%204.4,to%20the%20Chatham%20House%20report.

- Madeleine Rubenstein, (2012). Emissions from cement Industry. Columbia University. https://blogs.ei.columbia.edu/2012/05/09/emissions-from-the-cement-industry/

- Courland, Robert (2011). Concrete planet: the strange and fascinating story of the world's most common man-made material. Amherst, N.Y.: Prometheus Books.

- Lucy Rudgers, (2018). Climate change: The massive CO2 emitter you may not know about. https://www.bbc.com/news/science-environment-46455844

Acknowledgment

1. Dr. Vijaya Aravindan, Assistant Professor of Mechanical Engineering, SRM Institute of Technology

Additional Project Information

Research Plan:

Goal

To make commercially viable or special use concrete that can be made from raw materials in an environmentally friendly way and still have tensile, compressive, and flexural strength comparable to regular Calcium based concrete.

Societal Impact

Calcium Oxide is made primarily from Limestone by heating it and expelling Carbon Dioxide. Calcium Oxide does not occur naturally. However, Magnesium Oxide occurs naturally as Periclase. Magnesium Hydroxide exits naturally as Brucite. Zinc Oxide occurs as Zincite and together with other elements as Franklinite and Calamite. Magnesium Oxide can also be made by heating Brucite with is Magnesium Hydroxide. Heating it would produce just steam and not a greenhouse gas like Carbon Dioxide. If Magnesium concretes became mainstream, it will lead to a huge reduction in the amount of Carbon Dioxide we put into the atmosphere - possibly the entire 2.5 billion tons that we pump into the atmosphere for cement production could be done away with.

Procedure

The elements in the periodic table were analyzed systematically to find candidate elements for the alternative cement, based on cost, abundance, crystal strength, toxicity, among others. 13 candidates were identified. They were further analyzed and Magnesium was identified as the best candidate.

- Find which of Magnesium Oxide – Chloride/Sulfate/Phosphate cement is the best.

- Mix Magnesium Oxide with Magnesium Chloride and Silicon Dioxide

- Start with 50% Magnesium Oxide and vary Silicon Dioxide and Magnesium Chloride concentration in steps or 5% with Magnesium Chloride percentage between 5 and 25%

- Find the strength of concrete in each of the sample cores created in previous steps.

- Compressive strength

- Tensile strength

- Flexural strength

- Repeat Steps 1a to 1c with Magnesium Sulfate instead of Magnesium Chloride.

- Repeat Steps 1a to 1c with Magnesium Phosphate instead of Ammonium Phosphate Monobasic

- Find if the addition of Ferric Oxide or Aluminium Oxide or both improve the strength of the best candidate from Step 1.

- Add 2.5 % Iron III Oxide to 50% Magnesium Oxide, 30% Silicon Oxides, 17.5% Magnesium Chloride

- Add 2.5 % Aluminium Oxide to 50% Magnesium Oxide, 30% Silicon Oxides, 17.5% Magnesium Chloride

- Add 2.5 % Iron III Oxide and 2.5 % Aluminium Oxide to 50% Magnesium Oxide, 27.5% Silicon Oxides, 17.5% Magnesium Chloride

- Find the strength of concrete in each of the sample cores created in steps 2a-c.

- Compressive strength

- Tensile strength

- Flexural strength

- Test for participles of raw cement in the cured concrete

- Use large quantity of the best cement from Step 3.

- Shape the concrete to maximize the surface area.

- Leave it in warm water for more than 3 days.

- Use a water test strip to check for the presence of chloride or iron in the water.

- Find if the addition of slag and/or fly ash to Magnesium Oxide – Chloride – Ferric Oxide cement will increase strength and water resistance. Prepare samples with the composition listed below and compare it with Magnesium Oxide - Silicon Dioxide - Magnesium Chloride – Ferric Oxide from the previous step.

- Add 2.5 % Slag to 50% Magnesium Oxide, 27.5% Silicon Oxides, 17.5% Magnesium Chloride, 2.5 Ferric Oxide

- Add 2.5 % Fly Ash to 50% Magnesium Oxide, 27.5% Silicon Oxides, 17.5% Magnesium Chloride, 2.5 Ferric Oxide

- Add 2.5 % Slag and 2.5% Fly Ash to 50% Magnesium Oxide, 25% Silicon Oxides, 17.5% Magnesium Chloride, 2.5 Ferric Oxide

- Find the strength of concrete in each of the sample cores created in steps 2a-c.

- Compressive strength

- Tensile strength

- Flexural strength

- Test all the samples in water.

Data and Analysis

Step 1: Tensile, Compressive, and Flexural Strength will be calculated for Magnesium Chloride, Magnesium Sulfate and Ammonium Phosphate cement with Magnesium Chloride, Magnesium Sulfate, and Ammonium Phosphate concentrations 10%, 15%, 20% and 25%.

Step 2: Tensile, Compressive, and Flexural Strength will be calculated for samples without Ferric Sulfate, Aluminium Oxide and both.

Step 3: Water Test involves not calculation.

Step 4: Tensile, Compressive, and Flexural Strength will be calculated for samples without Slag, Fly Ash and both.

All the data will be graphed using scatter and radar plots.

Questions and Answers

1. What was the major objective of your project and what was your plan to achieve it?

To create cement that is eco-friendly in the ways it will be produced. And to create samples and test them out for strength. The strength should be comparable to regular Portland cement.

a. Was that goal the result of any specific situation, experience, or problem you encountered?

Yes. I saw a pie chart about sources of carbon dioxide. I was surprised to find that 8% of all the carbon dioxide humans put into the atmosphere comes from making cement alone!

b. Were you trying to solve a problem, answer a question, or test a hypothesis?

My hypothesis is that an alternative cement should be possible. I tested that hypothesis.

2. What were the major tasks you had to perform in order to complete your project?

a. For teams, describe what each member worked on.

Step 0: Identify candidate elements and screen them

Step 1: Identify compounds of that element that can be used for the cement

Step 2: Test Additives

Step 3: Test performance with water

Step 4: Test binders if necessary

3. What is new or novel about your project?

It's eco-friendly cement. Current types of cement are highly carbon -possible.

a. Is there some aspect of your project's objective, or how you achieved it that you haven't done before?

Yes, I never made so many concrete samples before.

b. Is your project's objective or the way you implemented it, different from anything you have seen?

Yes, I try to find a way to prevent the cement from leaching any of its contents.

c. If you believe your work to be unique in some way, what research have you done to confirm that it is?

The use of slag as a binder to prevent is not something new I have not seen anywhere in my online or library research.

4. What was the most challenging part of completing your project?

Finding a binder to control leaching of Chloride into the water.

a. What problems did you encounter, and how did you overcome them?

I tried several known binders to find the suitable one to keep Chloride bound to the concrete.

b. What did you learn from overcoming these problems?

Most problems can be solved if we try hard enough.

5. If you were going to do this project again, are there any things you would you do differently the next time?

This is my first time doing this project.

6. Did working on this project give you any ideas for other projects?

Yes, I would like to work towards creating carbon-negative cement. Magnesium Carbonate is made by reacting Magnesium Hydroxide with carbon-dioxide. I would like to use this property to create concrete that can gain immense strength over time by absorbing carbon dioxide from the air.

7. How did COVID-19 affect the completion of your project?

I wanted to get my samples tested at a commercial testing place or at a laboratory. But, it was not possible. So, I had to use the Baoshishan test apparatus at home.

2-minute Video Overview: https://youtu.be/6m-HEdyJKBM