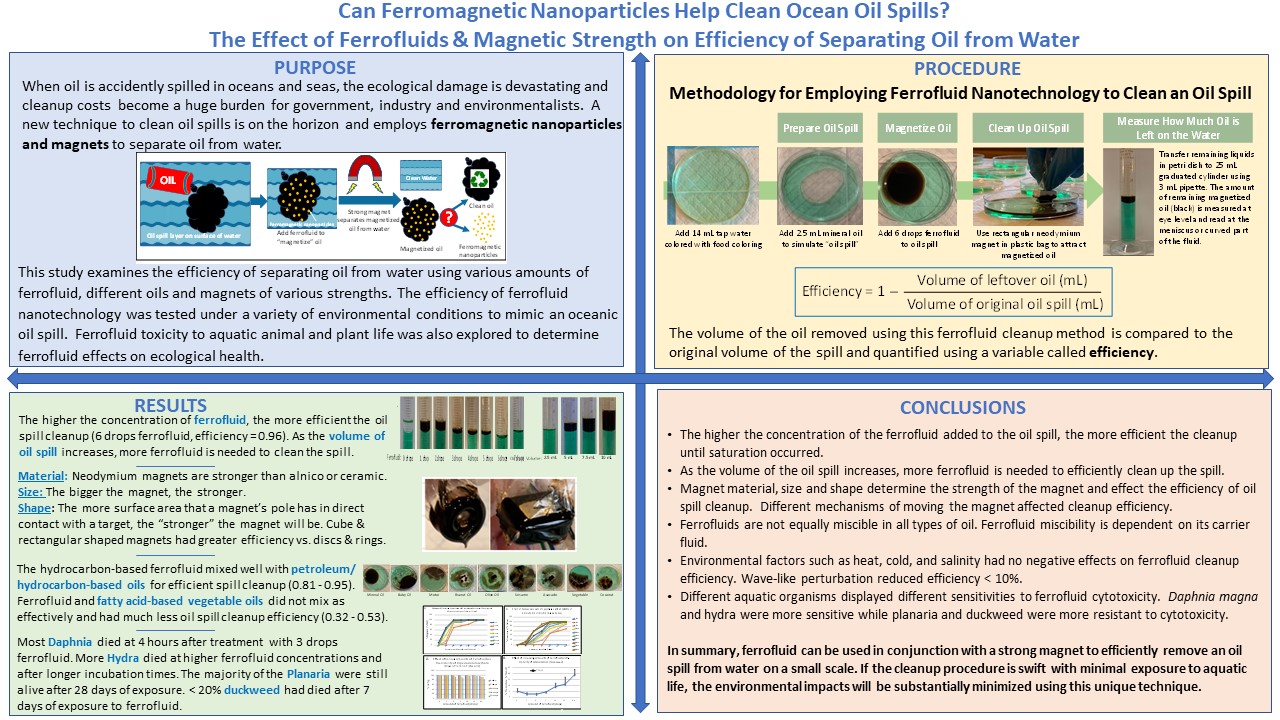

Can Ferromagnetic Nanoparticles Help Clean Ocean Oil Spills? The Effect of Ferrofluids & Magnetic Strength on Efficiency of Separating Oil from Water

Abstract:

Bibliography/Citations:

REFERENCES:

1. Andrea Thompson. FAQ: The Science and History of Oil Spills, Lifescience, April 2020. https://www.livescience.com/9885-faq-science-history-oil-spills.html

2. Oils Spills: Impact on the Ocean. Water Encyclopedia. http://www.waterencyclopedia.com/Oc-Po/Oil-Spills-Impact-on-the-Ocean.html #:~:text=It%20is%20estimated%20that%20approximately,disposal%20of%20used%20motor%20oil.

3. A Deadly Toll: The Devastating Wildlife Effects of Deepwater Horizon – and the Next Catastrophic Oil Spill. Center of Biological Diversity. https://www.biologicaldiversity.org/programs/public_lands/energy/dirty_energy_development/oil_and_gas/gulf_oil_spill/a_deadly_toll.html

4. Ocean Spills. National Oceanic and Atmospheric Administration. U.S. Department of Commerce. https://www.noaa.gov/education/resource-collections/ocean-coasts/oil-spills

5. How does oil impact marine life? February 26,2021. https://oceanservice.noaa.gov/fact/oilimpacts.html

6. BP paid a steep price for the Gulf oil spill but for the US a decade later, it’s business as usual. The Conversation. April 23, 2020. https://theconversation.com/bp-paid-a-steep-price-for-the-gulf-oil-spill-but-for-the-us-a-decade-later-its-business-as-usual-136905

7. Mayur Agarwal. 10 Methods for Oil Spill Cleanup at Sea. Marine Insight. https://www.marineinsight.com/environment/10-methods-for-oil-spill-cleanup-at-sea/

8. Beth Buczynski. MIT Magnets Could Pull Offshore Oil Spills from Water. National Geographic, September 20, 2012.

9. Larry Hardesty. How to clean up oil spills: MIT researchers devise a surprisingly simple but effective method for magnetically separating oil and water. MIT News, September 12, 2012. https://news.mit.edu/2012/how-to-clean-up-oil-spills-0912

10. Using Magnets and Nanotechnology to Clean Up Oil Spills. November 14, 2019. https://www.goudsmit.co.uk/using-magnets-and-nanotechnology-to-clean-up-oil-spills.

11. What Are Nanoparticles? Definition, Size, Uses and Properties. https://www.twi-global.com/technical-knowledge/faqs/what-are-nanoparticles

12. Size of the Nanoscale. National Nanotechnology Initiative. https://www.nano.gov/nanotech-101/what/nano-size

13. Tom Levitt. Cleaning up oil spills with magnets and nanotechnology. September 21,2012. http://cnn.com/2012/09/21/tech/oil-spill-magnets/index/html

14. Ferrofluids. Academic Kids Encyclopedia. http://academickids.com/encyclopedia/index.php/Ferrofluid

15. Nano Knowledge: Imagine and Discover a World You Can’t See. Discovery Place Rockingham. https://kids.discoveryplace.org/rockingham/stay-at-home-science/imagine-and-discover-a-world-you-cant-see.

16. Can Nanotechnology Help Clean Up Ocean Spills? Science Buddies, November 20, 2020. https://www.sciencebuddies.org/science-fair-projects/project-ideas/EnvEng_p036/environmental-engineering/can-nanotechnology-help-clean-up-ocean-oil-spills

17. How much salt is in the ocean? https://www.americanoceans.org/facts/how-much-salt-in-ocean/

18. Living Care Information for Daphnia magna and Daphnia pulex. https://www.carolina.com/teacher-resources/Interactive/care-guide-daphnia/tr10492.tr

19. Living Care Information for Planaria. https://www.carolina.com/teacher-resources/Interactive/care-guide-planaria/tr10534.tr

20. Biosafety Level Practices Chart. https://blink.ucsd.edu/safety/research-lab/biosafety/containment/chart.html

21. Ferrofluid Safety Data Sheet. https://www.homesciencetools.com/content/reference/SB-FERROKT.pdf

22. W. Brian Rowe. Principle of Modern Grinding Technology. Elsevier, April 1, 2000, p 133-144.

23. What Determines the Strength of a Magnet. January 20, 2020. http://www.usamagnetix.com.

24. The Different Types of Permanent Magnets. https://www.moleymagneticsinc.com/the-different-types-of-permanent-magnets/

25. The Various Shapes of Magnets and Their Uses. https://www.apexmagnets.com/news-how-tos/the-various-shapes-of-magnets-and-their-uses/

26. Factors That Affect the Strength of a Magnet

https://www.jobmastermagnets.com/Does-the-Shape-of-a-Magnet-Affect-Its-Strength

27. Amazing Magnets technical support. Amazingmagnets.com

28. Robert Kaiser. Process for cleaning up oil spills. US Patent 3635819A. https://patents.google.com/patent/US3635819A/en

29. Difference Between Vegetable Oil and Mineral Oil. http://www.differencebox.com/food/difference-between-vegetable-oil-and-mineral-oil/

30. Stephen K. Ritter. What’s that stuff? Motor Oil. Chemical and Engineering News. March 13, 2006. Vol. 84, Issue 11.

31. What is the difference between crude oil and vegetable oil? Petro Online. April 8, 2015. https://www.petro-online.com/news/fuel-for-thought/13/breaking-news/what-is-the-difference-between-crude-oil-and-vegetable-oil/34130

32. Beth Nolte. Tanking up with cooking oil. American Chemical Society ChemMatters, April 2001.

https://www.acs.org/content/acs/en/education/resources/highschool/chemmatters/past-issues/archive-2010-2011/cookingoil.htm

33. Marcus Zahn. Cleaning up oil spills with magnets at MIT. https://m.youtube.com/watch?v=ZaP7XOjsCHQ

34. Carolyn Federici and Jonathan Mintz. Oil Properties and Their Impact on Spill Response Options Literature Review. https://www.bsee.gov/sites/bsee.gov/files/osrr-oil-spill-response-research/1017aa.pdf.

35. Angelika Tkaczyk et. al. Daphnia magna Model in the Toxicity Assessment of Pharmaceuticals: A Review. Science of the Total Environment, Vol. 763, April 1, 2021.

36. Daniel A. Felix et al. It is not all about regeneration: Planarians striking power to stand starvation. Seminars in Cell & Developmental Biology. Vol. 87, March 2019, Pages 169-181.

37. G. Dave. Effects of waterborne iron on growth, reproduction, survival and haemoglobin in Daphnia magna. Comp Biochem Physiol C Comp Pharmacol Toxicol. 1984;78(2):433-8.

38. R.D. van Anholt et al. Effects of iron sulfate dosage on the water flea (Daphnia magna Straus) and early development of carp (Cyprinus carpio L.). Arch Environ Contam Toxicol. 2002.

39. X. Ding et al. Effects of Fe3+ on Acute Toxicity and Regeneration of Planarian (Dugesia japonica) at Different Temperatures. Biomed Res Int. 2019 Aug 22.

40. L.R.R. Souza et al. Iron oxide nanoparticle phytotoxicity to the aquatic plant Lemna minor: effect on reactive oxygen species (ROS) production and chlorophyll a/chlorophyll b ratio. Environ Sci Pollut Res 26, 24121–24131 (2019).

41. Goran Kovačević et al. Toxic effects of iron on green and brown hydra. Current Science Vol. 110, No. 4 (25 February 2016), pp. 502-504.

Additional Project Information

Research Plan:

MATERIALS:

- Fluid Nanotechnology Kit (Home Science Tools: SKU: SB-FERROKT)

- Ferrofluid, 50 mL

- Mineral oil, 60 mL

- Neodymium block magnet, 0.75” X “0.5” X 0.25” (L x W x H)

- Petri dishes, 90 mm x 15 mm

- Graduated cylinder, 25 mL

- Plastic graduated transfer pipettes (1 mL and 3 mL)

- Nitrile gloves

- Disposable lab coat and lab goggles

- Disposable clear plastic cups, 9 oz (266 mL) and 18 oz (532 mL)

- Plastic zip-loc sandwich bags (16.5 cm X 8.2 cm)

- Food coloring

- Morton’s Salt (1 LB or 737g)

- Spring water

- Thermometer (Celsius)

- Black Sharpie marker

- Bleach

- Paper towels and disposable under pads 23” X 36”

- Oils: Mazola Corn Oil, Bertolli Extra Virgin Olive Oil, Crisco Pure Canola Oil, Crisco Pure Vegetable Oil, Nature’s Promise Coconut Oil, Peanut Oil, Johnson’s Baby Oil, Prima Kitchen Pure Avocado Oil, Sesame Oil, Briggs & Stratton Engine Oil

- Magnets of different shapes, sizes and materials (neodymium, ceramic, alnico, samarium cobalt)

- Daphnia Magna water flea (Carolina Biological Supply, Item #: FAM_142330)

- Brown Planaria Flatworm Dugesia dorotocephala (Carolina Biological Supply, Item #: 132955)

- Green Hydra Chlorohydra viridissima (Carolina Biological Supply, Item #: 132801)

- Duckweed Lemna minor aquatic plant (Carolina Biological Supply, Item #: 161820)

PROCEDURES:

I. The Effect of Different Concentrations of Ferrofluid on Oil Spill Cleanup Efficiency16

1. Prepare the colored water to increase visibility: Add 400 mL of tap water to 18 oz (532 mL) plastic cup, add four drops of green food coloring and mix thoroughly to disperse in the water.

2. Prepare the “oil spill” in petri dishes: Using a 25 mL graduated cylinder, fill each petri dish with 14 mL of the green colored water. Use the 3 mL graduated pipette to add exactly 2.5 mL of mineral oil to each of the petri dishes. It is critical that each petri dish receives the exact same volume of oil in order to compare the results against each other. Aim carefully to release the oil in the middle of the petri dish.

3. Make the oil magnetic by adding the ferrofluid: Invert the bottle of ferrofluid with lid closed several times to mix the bottle before opening. Add 1, 2, 3, 4, 5, 6 or 7 drops of ferrofluid in the oil spill using a 1 mL graduated pipette. For one drop of ferrofluid, place the drop in the middle of the oil spill. For additional drops of ferrofluid, distribute the drops over the oil surface. Make sure that you have a control dish with no ferrofluid added. Make enough oil spills so that each condition can be tested in triplicate.

4. Clean up the oil spill with the neodymium magnet: Open a clean plastic sandwich bag and put the neodymium magnet (0.75” X 0.5” X 0.75” L x W x H) in one of the corners of the plastic bag. It is now ready to pick up the magnetized oil spill in the oil cleanup procedure.

i. Submerge the magnet slightly in the liquid and pass through the total oil spill in one slow movement. It is important to use the same method of moving the magnet through the oil since different methods of moving the magnet through the oil may influence the results.

ii. Wipe the plastic bag off with a paper towel.

iii. Place the magnet in the other clean and dry corner of the plastic bag and pass the magnet through the oil a second time. Discard the dirty plastic bag.

5. Measure how much oil is left on the water.

i. Using a 3 mL graduated pipette, transfer all of the leftover liquid (water, oil and ferrofluid) from the petri dish to a 25 mL graduated cylinder. Try to get as much oil out of the petri dish as possible since some will stick to the dish.

ii. Read the amount of oil left on top of the water (Figure 3). Keep the oil layer level with your eye.

iii. Discard the fluid in the cylinder in a waste cup. Rinse the cylinder with warm soapy water and dry the inside of the cylinder with a paper towel wrapped around a drinking straw.

6. Repeat steps 2-5 two more times for a total of three tests for each cleaning procedure.

7. Analyze the data by comparing the volume of oil removed using this cleanup procedure to the volume of the original oil spill and quantifying in a variable called “efficiency”. It is easier to measure the volume of oil left after the cleanup procedure than the amount of oil removed.

i. Calculate the average volume of leftover mineral oil from the 3 tests.

ii. Calculate the efficiency of the cleanup procedure using the following equation:

Efficiency = 1 - volume of leftover oil (mL)/volume of original oil spill (mL)

iii. Make a bar graph of the volume left over for the cleanup procedures and the control (no ferrofluid). Make a bar graph of the efficiency of each cleanup procedure and the control.

Safety Precautions:

· Ferrofluids are messy and stain skin, clothes and work surfaces. While conducting all experiments with ferrofluids ensure that the ferrofluid is contained. Put the ferrofluid in a secondary containment cup so it does not spill on surfaces. Keep paper towels handy to clean up any spilled ferrofluid quickly. Ensure that you are wearing a disposable lab coat, lab goggles and nitrile exam gloves. Place absorbent pads below work surfaces to protect against staining. Ferrofluid also has a strong smell so be sure to work in a well-ventilated area with windows open.

· Neodymium magnets used in these experiments are very strong magnets. Some have the ability to interfere or reset pacemakers. Never put a neodymium magnet in your mouth. It is important to ensure that fingers are not pinched in between magnets. Keep the magnets away from any magnetized materials, computers, cell phones, etc.

II. The Effect of Different Volumes of Oil Spills on Cleanup Efficiency

1. Prepare the “oil spill” in petri dishes: Using a 25 mL graduated cylinder, fill each petri dish with 14 mL of the green colored water. Use the 3 mL graduated pipette to add exactly 2.5 mL, 5 mL, 7.5 mL or 10 mL of mineral oil to three petri dishes so that each condition can be tested in triplicate. Aim carefully to release the oil in the middle of the petri dish.

2. Make the oil magnetic by adding the ferrofluid: Invert the bottle of ferrofluid with lid closed several times to mix the bottle before opening. Add 6 drops of ferrofluid in the oil spill using a 1 mL graduated pipette, making sure to distribute the drops over the oil surface. Make sure that you have a control dish with no oil added.

3. Repeat steps 4 through 7 in Section I methods above for oil spill cleanup and data analysis.

III. The Effect of Magnet Strength on Oil Spill Cleanup Efficiency

1. Prepare the “oil spill” in petri dishes: Using a 25 mL graduated cylinder, fill each petri dish with 14 mL of the green colored water. Use the 3 mL graduated pipette to add exactly 2.5 mL of mineral oil to three petri dishes (triplicate test). Aim carefully to release the oil in the middle of the petri dish.

2. Make the oil magnetic by adding the ferrofluid: Invert the bottle of ferrofluid with lid closed several times to mix the bottle before opening. Add 6 drops of ferrofluid in the oil spill using a 1 mL graduated pipette, making sure to distribute the drops over the oil surface.

3. Repeat steps 4 through 7 in Section I methods above for oil spill cleanup using the different types of magnets and data analysis.

Safety Precautions: Neodymium, alnico, ceramic and samarium cobalt magnets vary in their strength and some are quite strong. They may have the ability to interfere and reset pacemakers. Never put these magnets in your mouth and be very cautious not to pinch fingers between magnets. Keep these magnets away from computers, credit cards and other magnetized objects.

IV. The Effect of Different Ways of Moving the Magnet on Oil Spill Cleanup Efficiency

1. Prepare the “oil spill” in petri dishes: Using a 25 mL graduated cylinder, fill each petri dish with 14 mL of the green colored water. Use the 3 mL graduated pipette to add exactly 2.5 mL of mineral oil to three petri dishes (triplicate test). Aim carefully to release the oil in the middle of the petri dish.

2. Make the oil magnetic by adding the ferrofluid: Invert the bottle of ferrofluid with lid closed several times to mix the bottle before opening. Add 6 drops of ferrofluid in the oil spill using a 1 mL graduated pipette, making sure to distribute the drops over the oil surface.

3. Repeat steps 4 through 7 in Section I methods above for oil spill cleanup but this time varying the ways the magnet is moved across the oil including:

· Slow movement slightly submerged (few mm below surface of oil) as in Sections I, II, III

· Fast movement slightly submerged (few mm below surface of oil)

· Completely submerge magnet in oil (touch bottom of petri dish)

· Barely skimming surface of oil

· Hovering over the surface of the oil (~1 cm above the surface of the oil)

V. The Effect of Different Kinds of Oils on Oil Spill Cleanup Efficiency

1. Prepare the “oil spill” in petri dishes: Using a 25 mL graduated cylinder, fill each petri dish with 14 mL of the green colored water. Use the 3 mL graduated pipette to add exactly 2.5 mL of the respective oil to three petri dishes (triplicate test). Oils used include: Mazola Corn Oil, Bertolli Extra Virgin Olive Oil, Crisco Pure Canola Oil, Crisco Pure Vegetable Oil, Nature’s Promise Coconut Oil, Peanut Oil, Johnson’s Baby Oil, Prima Kitchen Pure Avocado Oil, Sesame Oil, Briggs & Stratton Engine Oil. Aim carefully to release the oil in the middle of the petri dish.

2. Make the oil magnetic by adding the ferrofluid: Invert the bottle of ferrofluid with lid closed several times to mix the bottle before opening. Add 6 drops of ferrofluid to each different type of oil spill using a 1 mL graduated pipette, making sure to distribute the drops over the oil surface.

3. Repeat steps 4 through 7 in Section I methods above for oil spill cleanup and data analysis.

VI. The Effect of Environmental Factors on Oil Spill Cleanup Efficiency

1. Prepare water conditions to mimic different environmental conditions:

a. Still water (as in Sections I, II, III, IV, V above): Using a 25 mL graduated cylinder, fill each petri dish with 14 mL of room temperature (22°C) green colored water. Conduct in triplicate.

b. Mimic cold ocean temperatures (7°C or 44.6°F): Using a 25 mL graduated cylinder, fill each petri dish with 14 mL of the green colored water that was chilled in a refrigerator to 7°C (44.6°F). Conduct in triplicate.

c. Mimic warm ocean temperatures (29°C or 84.2°F): Using a 25 mL graduated cylinder, fill each petri dish with 14 mL of the green colored water that was heated on a stove to 29°C (84.2°F). Safety Precaution: Be careful not to spill hot water on the skin to avoid burns. Conduct in triplicate.

d. Mimic salinity of the ocean: On average, seawater in the world’s oceans has a salinity of 3.5% (35g/L salt).17 Prepare salt water by adding 35 grams of Morton’s Salt to 1L of room temperature green colored tap water. Using a 25 mL graduated cylinder, fill each petri dish with 14 mL of the green colored salt water. Conduct in triplicate.

e. Simulate ocean waves: Using a 25 mL graduated cylinder, fill each petri dish with 14 mL of room temperature (22°C) green colored water. During the cleanup process, rock the petri dish back and forth while moving the magnet through the oil. Be careful not to spill the water while rocking. Conduct in triplicate.

2. Prepare the “oil spill” in petri dishes: Use the 3 mL graduated pipette to add exactly 2.5 mL of mineral oil to three petri dishes (triplicate test). Aim carefully to release the oil in the middle of the petri dish.

3. Make the oil magnetic by adding the ferrofluid: Invert the bottle of ferrofluid with lid closed several times to mix the bottle before opening. Add 6 drops of ferrofluid in the oil spill using a 1 mL graduated pipette, making sure to distribute the drops over the oil surface.

4. Repeat steps 4 through 7 in Section I methods above for oil spill cleanup and data analysis.

VII. The Effect of Ferrofluids on Aquatic Organisms

Upon receipt of the Daphnia magna (water flea), Brown Planaria Flatworm Dugesia dorotocephala and Green Hydra Chlorohydra viridissima cultures in the mail from Carolina Biological Supply Company, immediately unscrew the cap of the container and put it loosely on the top to let oxygen in, which these organisms need to survive.18,19 Duckweed Lemna minor aquatic plant arrives from Carolina Biological Company wrapped in a wet paper towel. Place the duckweed in an 18 oz plastic cup filled with spring water and they will float on the water. Keep all organisms at room temperature of 22°C.

Daphnia Magna Toxicity Assay:

1. Add 120 mL of room temperature spring water to 9 oz (266 mL) clear plastic cups labelled with the following amounts of ferrofluid to respective cups: 0, 1, 3, 5, 10, 15, and 20 drops. Use 3 cups for each ferrofluid amount.

2. Add 10 living Daphnia to each cup then add the respective drops of ferrofluid to the cup.

3. Wait until 2 hours have passed and then count living and dead Daphnia in each cup. Live Daphnia will move around the cup. Dead Daphnia do not move, lie on the bottom of the cup or float on the surface of the water. Repeat these observations at 4, 6, 8, 10, and 12 hours.

4. Calculate the average number and the percentage of dead and live Daphnia recorded for each ferrofluid concentration and the control over exposure time. Plot a dose-response-curve from the results where the dose (concentration of ferrofluid) is depicted on the x-axis and the response (% dead Daphnia) is represented on the y-axis.

Hydra Toxicity Assay:

1. Green Hydra attach to the walls and bottom of the 4 oz shipping cup, which holds 120 mL of spring water. Using the original packaging containing ~30 Hydra per cup, add the following amounts of ferrofluid to respective cups: 0, 1, 3, 5, 10, 15, and 20 drops.

2. Wait for 2 hours and count living Hydra in each cup. Sick Hydra will disintegrate and lose their structure.

3. Calculate the percentage of live and dead Hydra for each ferrofluid concentration and the control over exposure time. Plot a dose-response-curve from the results where the dose (concentration of ferrofluid) is depicted on the x-axis and the response (% dead Hydra) is represented on the y-axis.

Planaria Toxicity Assay:

1. Add 120 mL of room temperature spring water to 9 oz (266 mL) clear plastic cups labelled with the following amounts of ferrofluid to respective cups: 0, 1, 3, 5, 10, 15, and 20 drops. Use 3 cups for each ferrofluid amount.

2. Add 10 living Planaria to each cup then add the respective drops of ferrofluid to the cup.

3. Count living and dead Planaria in each cup every 24 hours for 3 weeks. Live Planaria swim around the cup on the sides, bottom and freely in the middle. Planaria also attach to side and bottom of cup; swirl the cup to awaken.

4. Calculate the average number and the percentage of dead and live Planaria recorded for each ferrofluid concentration and the control over exposure time. Plot a curve from the results where the concentration of ferrofluid is depicted on the x-axis and the % living Planaria is represented on the y-axis.

Duckweed Toxicity Assay:

1. Add 120 mL of spring water to 9 oz (266 mL) clear plastic cups labelled with the following amounts of ferrofluid to respective cups: 0, 1, 3, 5, 10, 15, and 20 drops. Use 3 cups for each ferrofluid amount.

2. Add ~50 living duckweed plants to each cup then add the respective drops of ferrofluid to the cup.

3. Count living and dead duckweed after 7 days. Live duckweed is green and dead duckweed is brown.

4. Calculate the percentage of dead and live duckweed recorded for each ferrofluid concentration and the control. Plot a dose-response-curve from the results where the dose (concentration of ferrofluid) is depicted on the x-axis and the response (% living duckweed) is represented on the y-axis.

Biological Agents and Risk Assessment:

The cultures of Daphnia magna, Hydra viridissima, Dugesia dorotocephala and Lemna minor are isolated from local ponds by Carolina Biological Supply Company. These organisms fall in the same line as the classification of all microorganisms within the United States of America being governed by the Public Health Service. Carolina Biological Supply Company under these classification regulations classifies these organisms as Biosafety Level/Shipping Class I. According to the Public Health Service’s definition for Biosafety Level/Shipping Class I, these organisms are considered to be non-pathogenic and as such would not be expected to cause harm to healthy people, animals or to the environment.20 All safety precautions and disposal methods must be strictly followed.

Safety Precautions and Disposal: For maximum safety, maintain proper handling, clean up and disposal of Daphnia magna, Hydra viridissima, Dugesia dorotocephala and Lemna minor. Nose and mouth should be kept away from tubes, pipettes or other tools that come in contact with the cultures. Gloves must be worn at all times. For disposal, add 5 mL of bleach to each cup with collected dead/live organisms, mix well and after 20 min pour down the toilet. Do not release in the wild.

Questions and Answers

1. What was the major objective of your project and what was your plan to achieve it?

The objective of my project was to study the efficiency of separating oil from water using various amounts of ferrofluid and magnets of various strengths (size, shapes, and materials). The study investigated if the ferrofluid will spread and mix through various oils and whether the magnet can remove the oil/ferrofluid mixture from the water. The volume of the oil removed using this ferrofluid cleanup method was compared to the original volume of the spill and quantified using a variable called efficiency. Efficiency is the volume of removed oil divided by the volume of the original oil spill. The efficiency value close to 1 indicates that almost all of the oil has been removed. An efficiency value of zero indicates that little oil has been removed and that the cleanup method is poor.16 The efficiency of ferrofluid nanotechnology was tested under a variety of environmental conditions to mimic an oceanic oil spill. Additionally, ferrofluid toxicity to aquatic animal and plant life was explored to determine ferrofluid effects on ecological health.

a. Was that goal the result of any specific situation, experience, or problem you encountered?

Crude oil is a fossil fuel that is used to make a range of fuels and products that allow us to heat our homes, operate our cars, produce electricity and power the economy. However, when oil from rigs, pipelines and tankers is accidently spilled in oceans and seas, the ecological damage is devastating and cleanup costs in terms of time, resources and money becomes a huge burden for government, industry and environmentalists. According to the US Department of Energy, 1.3 million gallons (4.9 million liters) of petroleum are spilled into U.S. waters per year.1 A major oil spill can lead to double that amount. Furthermore, it is estimated that more than 700 million gallons of waste oil enter worldwide oceans each year, with over half coming from land drainage and improper waste disposal of used motor oil.2

Oil spills have drastic effects to marine life. In 2010, an explosion at the BP Deepwater Horizon oil rig led to the largest marine oil spill in history. 206 million gallons of oil and 22,500 tons of methane were spilled into the Gulf of Mexico, 41 miles off the coast of Louisiana.3 Only 25% of the oil was recovered leaving 154 million gallons of oil at sea.3 Two million gallons of dispersant were spread to contain the spill causing more toxicity to ocean life. Over 82,000 birds, 6,165 sea turtles, 25,000 marine mammals and a vast number of fish were affected.3 For example, oiling can coat a bird’s wings making it unable to fly or strip away the otter’s fur leaving it susceptible to hyperthermia. Oil toxicity caused by dolphins and whales inhaling and ingesting oil can affect heart, lungs, immune function and reproduction and lead to death.4,5 Oil can make fish and shellfish unsafe for humans to eat.5 Unfortunately, rescue teams cannot recover and rehabilitate all wildlife impacted as a result of an oil spill. BP spent $15 billion in cleanup costs and another $20 billion in economic damages.6

Fortunately, oil density is less than water and, therefore, it floats on the water surface when it leaks or spills. As such, there are multiple historical methods to clean up surface oil spills but, unfortunately, these cleanup methods have varying scales and ranges of efficiency and can never remove 100% of spilled oil from the environment.7 For example, while booms and skimmers are effective in calm seas, they are very inefficient in rough waters like the ocean. Dispersants and burning have environmental consequences for marine life and the atmosphere. Furthermore, scientists need to be very careful that these cleanup methods do not cause additional harm to the environment and ecological health. Ferrofluid nanotechnology is on the horizon as a new method to clean ocean spills. Therefore, I wanted to explore whether ferrofluids and magnets could efficiently remove an oil spill from water and whether ferrofluids would cause harm to aquatic animals and plants.

b. Were you trying to solve a problem, answer a question, or test a hypothesis?

There were several TESTABLE QUESTIONS that I aimed to explore in my studies:

- Do ferrofluids with an oil-based carrier fluid added to spilled oil make it magnetic? How do various amounts of ferrofluids and oil spills affect efficiency of separating oil from water?

- Does this cleanup method have the same efficiency for all oils?

- Does the strength of the magnet affect the efficiency of oil removal?

- Do environmental factors such as currents, water temperature and salt vs. fresh water affect the efficiency of ferromagnetic nanoparticle oil removal?

- Do ferrofluids themselves have a toxic effect on aquatic organisms?

The following is my HYPOTHESIS that I wanted to prove:

If ferrofluids are added to an oil spill, then the oil will mix with water-repellant ferromagnetic nanoparticles and can be magnetically separated from water because magnets attract iron. The higher the concentration of ferrofluid and the stronger the magnet, the more efficient the oil removal.

2. What were the major tasks you had to perform in order to complete your project?

My project had seven subtopics that I wanted to explore. Each was a major task/step in completing the project.

- The Effect of Different Concentrations of Ferrofluid on Oil Spill Cleanup Efficiency: This entailed first developing the experimental system for cleaning up a small-scale oil spill. Using a fixed volume of oil spill, I needed to determine which concentration of ferrofluid was the most efficient at cleaning the spill. This would then be the condition used for exploring the other conditions/subtopics. Every condition for every experiment was tested in triplicate.

- The Effect of Different Volumes of Oil Spills on Cleanup Efficiency: This entailed increasing the volume of the oil spill to test the efficiency of a fixed concentration of ferrofluid.

- The Effect of Magnet Strength on Oil Spill Cleanup Efficiency: For this step, I needed to search many vendors to obtain magnets of different materials (neodymium, samarium cobalt, alnico, ceramic), different shapes (rectangle, cube, sphere, ring, disc) and different sizes. It was very important when comparing across material types that the size be keep the same since, typically, the bigger the magnet, the stronger it is.

- The Effect of Different Ways of Moving the Magnet on Oil Spill Cleanup Efficiency: For consistency across all experiments in this entire project, the rectangular block neodymium magnet was slightly submerged in the oil spill (few mm below surface of oil) and moved with a slow, gliding motion to enable oil spill cleanup. This experiment tested different ways of moving the magnet to enhance the cleanup efficiency. Several mechanisms were studied: slow movement slightly submerged (few mm below surface of oil) as in Sections 1, 2 & 3, fast movement slightly submerged (few mm below surface of oil), completely submerge magnet in oil (touch bottom of petri dish). barely skimming surface of oil, and hovering over the surface of the oil (~1 cm above the surface of the oil).

- The Effect of Different Kinds of Oils on Oil Spill Cleanup Efficiency: This entailed repeating triplicate tests with various petroleum hydrocarbon-based oils (mineral oil, Johnson’s Baby Oil, Briggs & Stratton Engine Oil) and vegetable cooking oils derived from the seeds, nuts and fruits of plants, which consist of fatty acids (linoleic, palmitic, oleic) and complex mixtures of triacylglycerols and diacylglycerols. (Mazola Corn Oil, Bertolli Extra Virgin Olive Oil, Crisco Pure Canola Oil, Crisco Pure Vegetable Oil, Nature’s Promise Coconut Oil, Peanut Oil, Prima Kitchen Pure Avocado Oil, Sesame Oil). The properties of the hydrocarbon-based carrier fluid were very critical to enable the ferrofluid to spread wide through the oil spill and form a stable suspension with the oil in order to “absorb” the oil in the pore of the ferromagnetic particles.

- The Effect of Environmental Factors on Oil Spill Cleanup Efficiency: Many traditional oil spill cleanup methods have drastically reduced efficiency under various environmental and atmospheric conditions. The purpose of this set of experiments was to examine the efficiency of ferrofluid nanotechnology in conditions that mimic the ocean (cold and warm ocean temperatures, salinity and waves).

- The Effect of Ferrofluids on Aquatic Organisms: The use of nanoparticles has been controversial due to the concerns that nanoparticles could have the ability to enter cells and damage marine life and cause still unknown environmental effects. Therefore, the purpose of these experiments was to examine the effects of ferrofluids on aquatic life. Daphnia magna (water flea) is a commonly used model for toxicity assessment of chemicals and pharmaceuticals.Therefore, Daphnia was used to examine the cytotoxic effects of ferrofluid. Hydra, planaria and duckweed were also used for studying cytotoxicity in this experiment.

3. What is new or novel about your project?

My project deals with an up-and-coming novel methodology to clean oil spills in water using ferromagnetic particles and strong magnets. This technology holds great promise for increasing the efficiency of oil spill cleanup under unfavorable oceanic conditions while reducing or negating further impacts on ecological health.

a. Is there some aspect of your project's objective, or how you achieved it that you haven't done before?

This is my first-time exploring ocean oil spills and I’ve learned so much about the devastating environmental impacts, the historical techniques to clean oil spills and the pitfalls of these methods to completely remove the spilled oil from the environment. This is my first involvement in learning about ferrofluids and new methodology on the horizon to apply to efforts for ocean spill cleanup. Working with ferrofluids (ferromagnetic nanoparticles in a carrier fluid with a surfactant to keep them from sticking together) was a new experience for me. Ferrofluids behave as normal liquids but in the presence of a strong magnet, the ferrofluid is pulled to the magnet, stiffens and behaves like a solid. It took a bit of trial and error for me to effectively handle the ferrofluid mixture and in developing a solid experimental technique for this project. Although I had previous experience with Daphnia magna water fleas, I also needed to learn the proper handling and care techniques for hydra and planaria to ensure their livelihood over the course of the experiment.

b. Is your project's objective, or the way you implemented it, different from anything you have seen?

In terms of science fair projects, I believe that my project is different since I explored this novel methodology beyond titrations of ferrofluid and oil spill volumes. I took a deep dive into oil cleanup efficiency of various materials, shapes and sizes of the magnets used to attract the ferrofluid/oil mixture as well as how the magnet is moved across the surface of the oil. I evaluated many different types of oils from petroleum-based hydrocarbon oils to fatty acid vegetables oils to investigate ferrofluid miscibility. I also recapitulated an oceanic environment in terms of water temperature, salinity and wave-like perturbations to examine environmental factors that affect oil spill cleanup efficiency. Furthermore, the use of nanoparticles has been controversial due to the concerns that nanoparticles could have the ability to enter cells and damage marine life and cause still unknown environmental effects. Therefore, I conducted studies to examine the effects of ferrofluids on several species of aquatic life, including the Water Flea Daphnia magna, Planaria flatworm Dugesia dorotocephala, Green Hydra Chlorohydra viridissima and the Duckweed Lemna minor aquatic plant.

c. If you believe your work to be unique in some way, what research have you done to confirm that it is?

In a Google search and a PubMed search, there were a number of journal publications demonstrating that that waterborne iron inhibited daphnia, hydra, planaria and duckweed growth, reproduction and survival. There were some limited journal articles that examined Fe2O4 and Fe203 nanoparticle effect on daphnia, planaria and duckweed. However, I did not come across studies that specifically tested ferrofluid effects on these aquatic organisms. In future studies, it would be important to differentiate between the ferrofluid/ferromagnetic nanoparticle toxicity and general sensitivity to iron for sensitive organisms such as daphnia and hydra.

4. What was the most challenging part of completing your project?

The most challenging part of the project was handling the ferrofluid. Ferrofluids are very messy and stain skin, clothes and work surfaces. Personal protective equipment was important as well as secondary containment for the ferrofluid. The neodymium magnets used in these experiments are very strong magnets. The attracted each other easily and it was very difficult to pull them apart without pinching fingers.

a. What problems did you encounter, and how did you overcome them?

I encountered the following problems during this experiment:

1. A very small amount of residual oil remains in the petri dish after transfer to the graduated cylinder for measurement. This may bias the results toward a more efficient cleanup. However, this was consistent and systemic with all petri dishes and, therefore, should not have significant effects on the calculation of the efficiency across samples. Bubbles in the graduated cylinder can also influence the accuracy of measuring how much oil volume remained. This was overcome by fully cleaning the graduated cylinder between trials so that residual oil droplets do not interfere with reading the meniscus. It is also very important in creating the oil spill that all drops of ferrofluid be placed directly on the oil. If ferrofluid accidentally drops on the water instead of the oil spill, it will sink to the bottom as droplets and not fully magnetize the oil.

2. For the different magnets study, one potential source of error was the manner in which the clear plastic sandwich bag covered the magnet. For square or rectangular magnets, the plastic bag sat flat against the surface of the magnet. However, with the disc, sphere, and ring-shaped magnets, the plastic bag was somewhat bunched around the magnet. This may influence the strength of the magnet to attract the ferrofluid due to the gaps between the magnet and the target. Therefore, it was important to smooth out the plastic bag as much as possible.

3. The viscosity of the various oils used was of different consistency and, therefore, more or less oil can be transferred from the petri dish to the graduated cylinder. Due to the different viscosities, the transfer may not have been systemic and there could be variations of how much residual oil is left over in the petri dish. Also, because the ferrofluid did not disperse as well in some oils and sank to the bottom of this dish, the inability to mix well with the oil would make the oil cleanup process less efficient. This highlights the importance of the carrier fluid compatibility.

4. For mimicking ocean-like conditions, one challenge is that the petri dish was shallow and only contained 14 mL of water, not allowing very forceful shaking without spilling the water/oil spill. While conducting this experiment with waves, it is important that the ferrofluid drops are added directly to the oil spill. If the ferrofluid drops hit the water, then they will sink to the bottom resulting in less cleanup efficiency.

5. In studying the effect of ferrofluids on aquatic life, without an oil spill in the water, the ferrofluids in an oil-based carrier fluid sink as droplets at the bottom of the cup and did not disperse. Since the ferrofluid did not disperse efficiently, it might not come in contact with the aquatic organisms as effectively. The ferrofluids also leave an oily film (most probably the carrier fluid) floating on the surface of the water and sides of the cup, which increased with increasing amounts of ferrofluid. Some Daphnia got stuck in the oil on the side of the cup and it prevented them from swimming which hastened their demise. To definitively determine if Daphnia are cytotoxic to ferrofluid, a ferrofluid with a water-based carrier should be used to better disperse the ferrofluid throughout the cup. This would rule out the variable that Daphnia were killed due to getting stuck in the oil residue vs. cytotoxicity due to the ferrofluid itself. Planaria, duckweed and hydra were unaffected by the oil floating on the water’s surface. It is important to note that these experiments with daphnia, hydra and planaria could not be conducted in the 14-mL petri dish since these organisms can easily deplete the oxygen in the smaller volume of water and lead to the death of the culture. Therefore, these experiments were carried out at a larger volume (120 mL).

6. Ferrofluids are very messy and have a strong odor. I learned quickly that it was necessary to ventilate the room by opening windows and turning on the exhaust fan.

b. What did you learn from overcoming these problems?

By overcoming these problems during the course of the experiments, I learned how to best reduce potential sources of error to ensure more precise measurements and less experimental variation between replicates.

5. If you were going to do this project again, are there any things you would you do differently the next time?

Making the following changes/additions to this project would help to expand the project:

- In these experiments, ferrofluid nanotechnology was used to clean ocean spills at a small scale. I would like to scale these volumes accordingly. 6 drops ferrofluid in 2.5 mL oil spill, 12 drops ferrofluid in 5 mL oil, 24 drops ferrofluid in 10 mL oil, etc.)

- For studies in aquatic organisms, I would like to repeat these experiments with a ferrofluid in a water carrier so it would disperse efficiently to get a more accurate assessment of cytotoxic effects. This would rule out the variable that Daphnia were killed due to getting stuck in the oil residue vs. cytotoxicity due to the ferrofluid itself.

- In regards to testing the effect of different ways of moving the magnet on oil spill cleanup efficiency, the next test that could be performed to improve efficiency is increasing the number of passes with the magnet through the oil/ferrofluid mixture. Perhaps less ferrofluid would be needed if you increase the number of passes with the magnet.

- In regards to testing different oils with varying viscosities, it would be good to test ferrofluids with other carrier fluids to see if the ferrofluid could disperse better through the various oils for more efficiency cleanup.

- For emulating oceanic conditions, a deeper container would allow more rigor in creation of “ocean-like” waves. Ideally, at a larger scale, the agitation which occurs through wave action should enhance the dispersion of ferrofluid in the oil slick improving efficiency compared to other methods.

6. Did working on this project give you any ideas for other projects?

For future experiments, I would like to investigate the following:

- The big question remaining is if this method of using ferrofluid nanotechnology to clean oil spills is scalable to oceanic levels. In this experiment, 6 drops of ferrofluid were used to clean up a 2.5 mL oil spill in 14 mL of water. The efficiency could be further investigated by double or tripling the quantities. For example, comparing the efficiency of using six drops ferrofluid to clean up 2.5 mL of oil, twelve drops for 5.0 mL, etc. These studies could also be scaled to a larger volume in a baby pool or tub and then into sea water depending on whether a magnet large enough could be acquired and ferrofluid quantities obtained.

- This project could be expanded to look at ferrofluids with different carrier fluids and how they act across different environments and oil types. For toxicity tests, it would be important that the carrier fluid be miscible with water. One could research how people make up their own ferrofluid with jet-printer ink and optimize it to clean up a specific oil spill.

- To more extensively test the effects of ferrofluid toxicity on marine life and ecological health, this project can be expanded to include a larger variety of aquatic plants (i.e., algae or Elodea, etc.) and marine animals (i.e., snails, fish, shellfish etc.). Since microorganisms play a large part in ecosystems and the food chain, it would also be good to include bacteria and plankton.

- One can also inquire if different life stages of Daphnia or other aquatic organisms (baby, juvenile or adult) react the same way to ferrofluids.

- It would also be very interesting to test the effects of ferrofluids on human-derived cell lines in culture to assess the safety risk posed to environmentalists and scientists involved in large scale oil spill cleanups.

- It would also be interesting to study how different sizes, shapes, surface areas, and coatings of the ferromagnetic nanoparticles affect their properties to “magnetize” oil and the subsequent cleanup efficiency.

- The present studies showed that a strong magnet can separate the oil/ferrofluid mixture from the water. The clean water can then be returned to sea. One can elucidate the best processes to “demagnetize” the oil (i.e., remove the ferromagnetic nanoparticles from the oil) in order recycle the oil for use in fuels and products.

7. How did COVID-19 affect the completion of your project?

Other than minor shipping delays, COVID-19 did not have any significant effect on the completion of my science project.